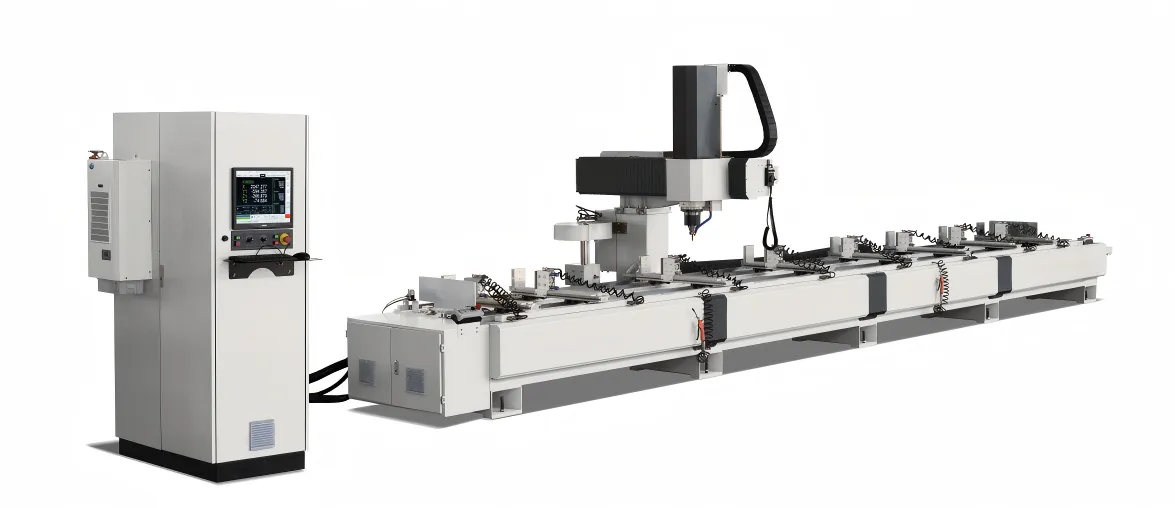

GNGS3Z-CNC-7000

High-Speed 3-Axis CNC Machining Center

Key Features

- Using advanced industrial CNC systems with a friendly machine interface, operation is simple.

- Suitable for aluminium, aluminium and wood composite profiles, light copper alloys, and u-PVC profile processing.

- Completes milling, drilling, chamfering, grooving, and other multifunction precision machining in a single clamping.

- Constructed with a high-strength welded structure, heat-treated and annealed to ensure high rigidity and stability.

- Uses imported high-precision linear guideways, ball screws, gear racks, and servo motors for smooth motion and high-accuracy positioning.

- Equipped with a high-quality imported automatic tool changer and high-speed motorised spindle for stable rotation, low noise, and strong cutting performance.

- Tool magazine features a 12-station capacity with adjustable pneumatic special fixtures for efficient processing.

- Dual worktables allow two profiles or two profile types to be machined simultaneously with interactive feeding and no interference.

- Incorporates multiple safety protection structures to ensure operator safety.

Technical Specifications

| Input power supply | 380V / 50Hz |

|---|---|

| Total power | 12.5 kW |

| Spindle power | 7.5 kW |

| Spindle speed | 0 to 18,000 rpm |

| Working air pressure | 0.5 to 0.8 MPa |

| X-axis transverse travel | 7000 mm |

| Y-axis longitudinal travel | 960 mm |

| Z-axis vertical travel | 300 mm |

| X-axis feed speed | 0 to 60 m/min |

| Y-axis feed speed | 0 to 30 m/min |

| Z-axis feed speed | 0 to 20 m/min |

| Repeat location accuracy | �0.02 mm |

| Roughness Ra | 6.3 �m |

| Overall dimensions | 11,300 _ 2,350 _ 2,550 mm |

| Weight | approximately 4000 kg |